Désormais interdite, la dorure par le procédé or-mercure au creuset, appelé amalgame, a longtemps représenté l’excellence de la décoration du bronze. Le dépôt de matière noble pénétrait toutes les microporosités du métal et offrait une dorure d’une grande résistance.

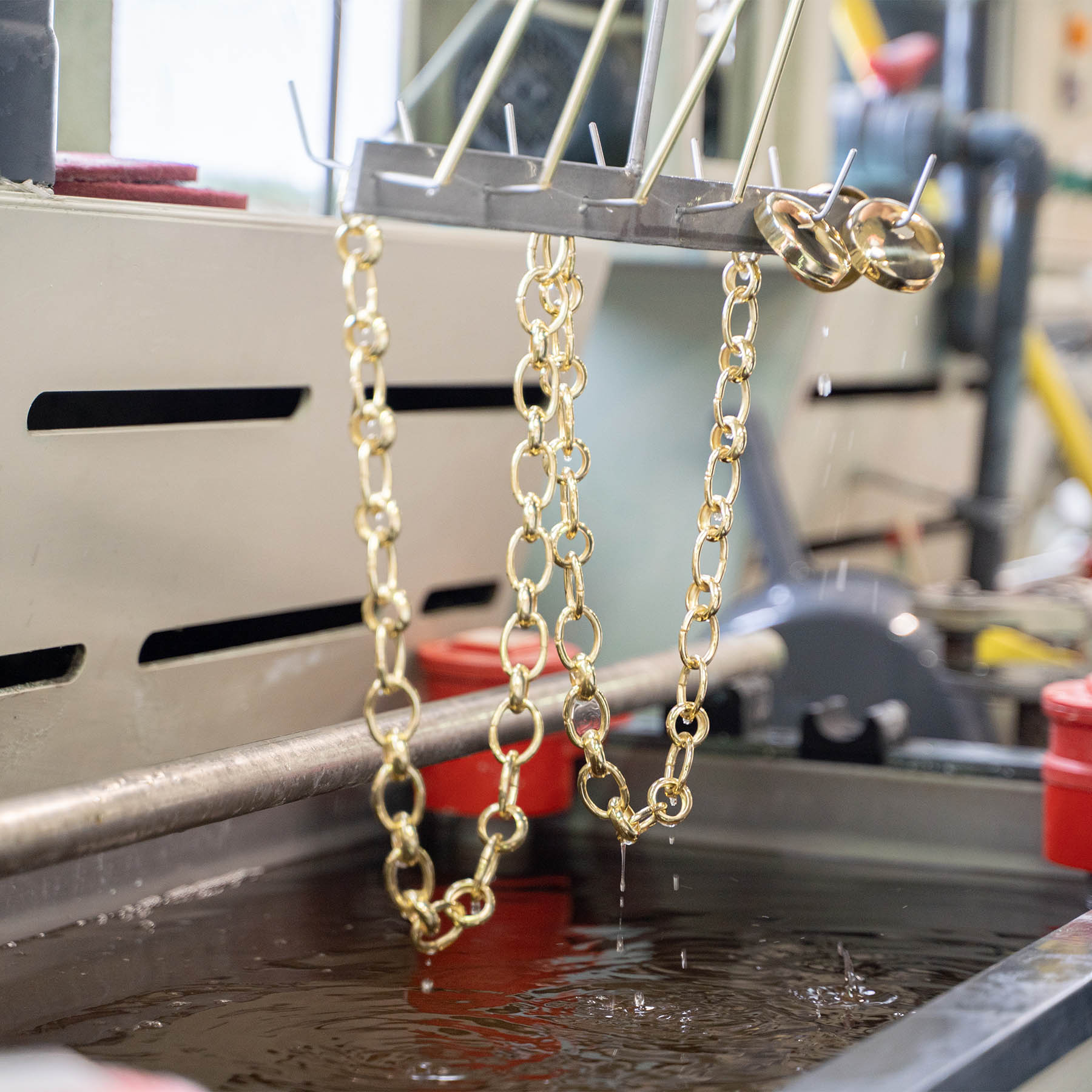

De nos jours, on utilise principalement la dorure par électrolyse. Dans un bain de sels, on plonge deux électrodes métalliques formant ainsi une pile. Sous l’effet d’un courant électrique, on provoque le déplacement de molécules métalliques d’une électrode vers l’autre, de l’anode vers la cathode. Résumer le traitement par l’électrolyse au fait de déposer un métal noble ou non sur un support est bien trop simple. Par ailleurs, pour que la magie opère, l’opération s’avère délicate au vu des normes environnementales en vigueur.

Ainsi, nous avons doté nos ateliers de traitements de matériaux, d’outils dernière génération tels qu’un évaporateur pour un recyclage des eaux de rinçage ce qui nous place dans une optique de rejet zéro pour l’environnement. De la même manière, un suivi bimensuel des teneurs en métaux de nos électrolytes a été mis en place. Chaque effluent, chaque bain usagé a une traçabilité en vue d’une destruction et/ou d’un recyclage par nos partenaires leaders en la matière. Grâce au professionnalisme de nos artisans metteurs aux bains, nous sommes en mesure de proposer un grand choix de teintes et de finitions.